.

The series of procurement disasters around the world is long and impressive. Projects lasted far to long (some lasted for three decades), busted their budget badly, produced mediocre or unsafe equipment, didn't meet the forces' real needs, were cancelled after high R&D costs or a combination of several such failures.

It's astonishing that the problem isn't under control, for the lessons were learned and could be implemented:

* No cost-plus contracts that motivate the supplier to bust the original budget.

* Neutral yet competent cost estimates are necessary because pro-program persons and institutions downplay (lie about) the costs.

* No political decision to stretch a program, for this increases the cost more than lending money for a timely program execution.

* Program managers need be loyal to the taxpayer, not to their project.

* Program managers need to be held responsible for (lack of) performance.

* Research and development need to be separated to keep technology risks down and avoid costly delays.

* The armed service needs to have the (technical) competence to define what it needs.

* Do not force multiple armed services to agree on a "joint" product. At least don't let them believe that they might get a custom development just for their service if there was no joint project. This never works out well.

* Do not allow "upgrades" that come close to the cost of a new product.

* Do not stare at the modernity of the product at the beginning of its operational service. Look at the average modernity over its lifetime. It may be better to replace mediocre products more often than to buy one super product and stick with it for a decade after its obsolescence.

* Small development cost items should be developed with industry capital.

* Off-the shelf products very often meet or exceed the requirements and should be bought.

* The state must not become soft and grant waivers over the original contract (build a tough reputation by enforcing contracts).

* Good contracts and requirements coupled with a tough procurement stance on the same allow for a very lax project supervision that doesn't burden the supplier with paperwork.

* Development requirements creep needs to be mostly avoided, this can be pone by requiring very high-level agreement for every change of requirements during a development project.

* Block special interests.

* Do not develop a product if you need only small quantities and could buy something off the shelf.

* "Perfect is the enemy of good."

* Do not allow your supplier to treat you as a low-priority customer. The taxpayer's interests deserve above-average engineers and priority!

* Do not allow suppliers to misunderstand the defence budget for a subsidy pool.

* Do not develop a major product in cooperation with the French. They will bail out once it becomes irrefutable that the product won't be "100% Made in France".

* Punish low performance of bidders in previous contracts by giving contracts to their competition.

* Do not encourage industrial concentration in mega corporations.

* Break up mega corporations with a competition protection act or by pressuring them to disintegrate into cooperating yet fully independent companies by withholding contracts.

* Last 10% of performance causes 30% of the costs, so KISS (keep it simple, stupid).

* Early development phase fixates 80% of costs (total development, per unit), so get it right soon.

* Think in the long term. Don't muddle through all the time, dare to standardise ideal calibres and vehicle families even if that's in contrast with existing inventories.

* Don't launch a development project if the future availability of funds for full development and production is questionable.

* Do not combine an whole army reform program into a bundle of development projects. Launch a development project for the link instead (communication standard and hardware).

* Do not allow fashions to take over your R&D department. Chase the proponents of fashions that violate common sense out of the ministry.

* Quality is overemphasized in peacetime, quantity is essential in wartime. Do not allow designs that are not affordable in quantity.

* Do not overemphasize platforms over ammunitions, spare parts and training funds.

* Use clear and honest information when informing parliament and public, do not misguide and conceal with 6+ definitions of "cost" or other trickery.

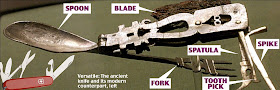

* Avoid one-trick ponies. Versatility is a value in itself.

* Demand and enforce that all public servants and soldiers involved in research or development or procurement projects sign a commitment with a huge contract penalty that keeps them from working directly or indirectly for the industry. Relieve those who reject it.

* Agree with the major opposition party if you're about to launch a development & procurement project that is despite observing all these rules still expected to last longer than your government coalition.

I wrote this list in 30 minutes without dedicated research, just out of my memory. The lessons learned are really obvious. There are only two explanations for why military procurement efforts are still so often a mess: Incompetence and evil.

It looks to me as if politicians don't do their job, followed by lower ranks mixing incompetence, red tape caused by incompetence and inappropriate interests into the problem.

Any reform needs to be a top-down effort. It's therefore appropriate to hold politicians (especially minister of defence and his highest tier secretaries) responsible for every failure that began when they were in office. Such gross failures should haunt them even after their continued their political career in opposition or another office.

S O

.