There are two main approaches to fragmentation of high explosive munitions:

(1) You encase the explosive with steel and let the explosion blow apart this simple casing into many fragments (= the old approach)

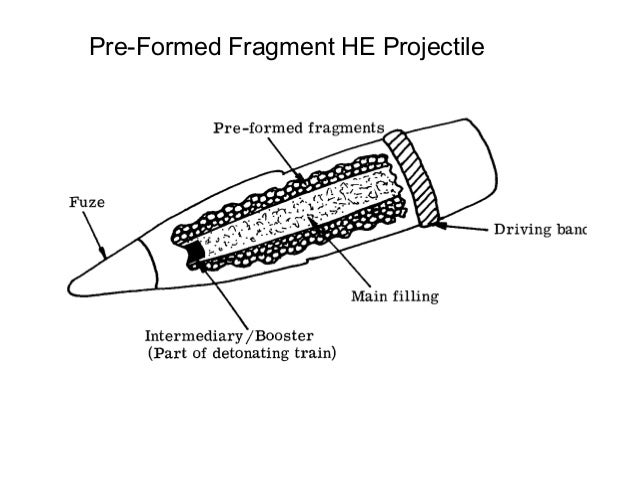

(2) You encase the explosive with pre-defined fragments (often steel balls) of mostly identical size (= becoming more and more typical)

|

| An old style externally serrated hand grenade; |

| too few and too large fragments (inefficient). |

This hybrid is the most typical one, but even with this approach you'll have very few very large and powerful fragments and a huge quantity of tiny fragments that become inefficient after a few metres of flight. "Soldat und Technik" issue V/1996 had an article which mentioned a typical example for a classic HE frag shell fragmentation:

0.1-1.0 g: 77% of fragments

1.0-10.0 g: 21% of fragments

10.0 -1 40.0 g: 1% of fragments.

Another example for WW2 shells with antiquated weight measurements is here.

| fragments (and their speed) from German WW2 88 mm Flak (source) |

| Fragments from non-serrated steel shell (WW2) source |

The steel quality influences the fragment sizes; ductile steel for bigger, brittle steel for smaller fragments.

Protection against this kind of fragmentation is a lottery. Even protected vehicles may be penetrated by the very few most powerful fragments, but very lightweight "flak vests" (~ 3 kg) protect against the vast majority of fragments (and weaken most of the others in their effect).

So this makes on the one hand very lightweight (low area density) protection meaningful and on the other hand it makes it very hard to ensure survival at short distances.

A ballistic helmet for example may stop almost all fragments of a HE shell, but at the same time it would stand no chance against the few big fragments without being much too heavy.

So this makes on the one hand very lightweight (low area density) protection meaningful and on the other hand it makes it very hard to ensure survival at short distances.

A ballistic helmet for example may stop almost all fragments of a HE shell, but at the same time it would stand no chance against the few big fragments without being much too heavy.

|

| Modern defensive hand grenade; |

| many same-sized small predefined fragments |

The fragments are mostly identical to each other (the fuse also turns into fragments).

Protection against this is very tricky. You may still use lightweight protection, but it would only matter at all at considerable distances from the explosion, where the probability of being hit by a fragment is much reduced anyway. On the other hand, the fragments may be designed to penetrate even quite heavy protection (equal approx. to a 7.62 long rifle cartridge AP bullet) at useful distances from the explosion.

Matters are being made more complicated by different fragment sizes being used in different munitions. You can expect much bigger, more powerful predefined fragments in an artillery shell than in a hand grenade since the desired lethal radius is much greater and they're also meant to do damage against equipment.

The result of the difference between old and new fragmentation concepts is that the fragmentation protection criteria and concepts should be very different depending on what threat you face.

As of now, old style (at most internally serrated) HE munitions and bomblets with weak fragments can be expected from the Russian army. This means that the established concepts - particularly the lightweight fragmentation protection - still make sense, and will continue to do so for at least about a decade.

There is little reason to expect a timely reaction to such a creeping change. We will likely see huge inventories of legacy vehicles and vests that follow badly outdated protection concepts (or are simply overweight) in the 2030's.

related:

2009-05 Body armour

2009-11 Body armour (update)

2011-01 Another shot at the historical failure of fragmentation protection vest procurement

S O

defence_and_freedom@gmx.de

.

*: This is always an important factor. The STANAG standard takes into account the distance from the explosion for this reason.

P.S: So far the armed bureaucracies pride themselves in "more is better". Better materials lead to better protection instead of lighter weight. Ballistic helmets used to have 1-1.1 mm steel; nowadays they're capable of stopping bullets of powerful handguns or even some assault rifles. I'm in favour of modesty and self discipline and would literally prefer a "90%" solution. This, of course, only works as long as the bottom 90% of fragments are weaker than the top 10%. A lightweight helmet of today would be almost useless against 100+ mm calibre HE shells with preformed fragments while being just fine against weaker threats, including ~3/4 of the fragments of those 105-155 mm projectiles that lack preformed fragments. It takes self-discipline to limit protection instead of making helmets as heavy as can be excused.

Now a bit more complicated: This is about diminishing returns; some rewards are easily gained, but at some point it's better to stop. A hypothetical warhead with all fragments being identical would not create clearly diminishing returns from increasing fragmentation protection against explosions at a set distance greater than the lethal blast radius. So in such a hypothetical simplified case there would be no sensible cut-off point where to stop adding protection other than the frag protection level required to survive fragments just outside of the lethal blast radius.

P.S: So far the armed bureaucracies pride themselves in "more is better". Better materials lead to better protection instead of lighter weight. Ballistic helmets used to have 1-1.1 mm steel; nowadays they're capable of stopping bullets of powerful handguns or even some assault rifles. I'm in favour of modesty and self discipline and would literally prefer a "90%" solution. This, of course, only works as long as the bottom 90% of fragments are weaker than the top 10%. A lightweight helmet of today would be almost useless against 100+ mm calibre HE shells with preformed fragments while being just fine against weaker threats, including ~3/4 of the fragments of those 105-155 mm projectiles that lack preformed fragments. It takes self-discipline to limit protection instead of making helmets as heavy as can be excused.

Now a bit more complicated: This is about diminishing returns; some rewards are easily gained, but at some point it's better to stop. A hypothetical warhead with all fragments being identical would not create clearly diminishing returns from increasing fragmentation protection against explosions at a set distance greater than the lethal blast radius. So in such a hypothetical simplified case there would be no sensible cut-off point where to stop adding protection other than the frag protection level required to survive fragments just outside of the lethal blast radius.

Old style externally serrated hand grenades were serrated this way because of ergonomy, not because of fragmentation, as far as I know. Such types as Russian F-1 hand grenade were even produced with cast iron casing, which means a little bit different fragmentation diagram.

ReplyDeleteFrom Russian army you can expect mortar shells with cast iron casing even today. (Although there were rumours about field tests of new mortar ammunition with strange fragmentation pattern (aka "microfragments") in Shirokyne, Ukraine.)

What do you think about Denel`s "generous" 105 mm shell with tungsten bullets?

That's often claimed, but the original intent is likely lost to history because this design's origins go back to the First World War.

DeleteJane's Infantry Weapons warns that this Soviet/Russian hand grenade produces (few) fragments lethal out to 200 m. The big, thick chunks of cast steel do not disintegrate into small fragments.

Tungsten is rather expensive (carbon steel price x 50). Countries with budget problems should limit HE such as 105 mm M1130 to fire missions for lethality, and prefer older HE shells for suppression.

Former Czechoslovakia produced old, long outdated Soviet (in fact French WW1) fragmentation hand grenades F1 well into the eighties and you can still find some documentation online (in Czech). Grey cast iron casing produced smaller fragments than construction steel. Of course, some few big fragments were still possible.

ReplyDeleteThere were generally two reasons for grey cast iron used in construction of old style Soviet grenades and mortar bombs: First, better fragmentation pattern than steel, and second, war economy (cast iron is easy to produce even under decentralised, half industrial conditions, this is not as energy intensive as steel - and you can use steel where you need it more). According to videos from Libya or Syria, this production model is still relevant in some parts of the world, even today. If besieged Aleppo can produce cast iron mortar bombs, almost everybody can.

I think tungsten is first of all important strategic raw material - and Denel`s artillery shell with tungsten balls is imo generally not very good idea.

Sven, the only shell that is pre-fragmented in the manner you describe is the 120mm APAM. Its casing is designed to break up into pieces large enough to penetrate body armor. In this regard, it seems to be the exception to the rule.

ReplyDeletehttp://www.dtic.mil/ndia/2007gun_missile/GMTuePM2/KurzikPresentation.pdf

DeleteWell, I stand corrected. Thats a pretty impressive shell.

Delete